Automated tugger train Factory Train FT600/FT900 –Autonomous tugger train for indoor and outdoor use

The Factory Train automated tugger train is an innovative driverless transport system (AGV) for use in both indoor and outdoor environments. As an automated guided vehicle system, the autonomous tugger train offers flexible levels of automation - from semi-automated processes to fully automated control during driving as well as loading and unloading. The Factory Train FT600 and FT900 tugger train series have been specially developed for automated logistics processes and are ideal for use as outdoor AGVs. With extremely high tracking accuracy and precise positioning accuracy during the loading process, these autonomous tugger trains ensure efficient, safe and reliable automation of your warehouse and production logistics.

With fully automated driving, our system takes over all driving tasks and precise positioning for transfer processes completely automatically. A driver or operator is no longer necessary, as all driving functions are fully performed by the tugger train itself.

Our automatic navigation is based on state-of-the-art geonavigation/contour navigation, which ensures precise and reliable control of the autonomous tugger train system. Depending on the location and specific requirements, a different type of navigation can also be used, such as satellite navigation. For particularly complex or diverse operating environments, it is also possible to use different types of navigation within the AGV - so-called hybrid navigation. This flexible combination ensures maximum efficiency and safety in autonomous control.

With our fully automated navigation system, you can optimise your logistics processes, reduce personnel costs and increase safety in your warehouse or production environment.

Fully automated loading and unloading

Efficient and safe loading and unloading processes are crucial for smooth logistics. With our innovative load carrier systems, we offer customised solutions that automate your processes, speed them up and make them safer. Whether connecting to conveyor technology or handling different good carriers - our systems are designed for maximum precision and flexibility.

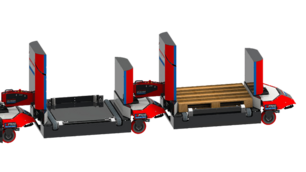

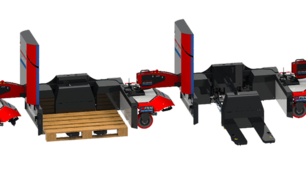

Various load carrier systems are available for automated loading processes: These include load carriers with conveyor technology superstructures (e.g. roller conveyors, accumulation conveyor chain, etc.) for automated transfer to/from roller conveyors. Or load carriers with automatically extending telescopic forks for picking up secured/braked pushable good carriers standing on the floor, such as trolleys/roll racks or pallets (crosswise and lengthwise).

Automated load carriers with conveyor technology superstructures

Our load carriers with conveyor technology superstructures are specially designed for the automated transport and transfer of goods. They are equipped with roller conveyors, accumulating conveyor chains or other conveyor technologies that enable a seamless connection to stationary conveyor lines. The vehicle docks at the source or sink with millimetre precision, while the internal roller conveyor adjusts to the height of the stationary conveyor system. This means that goods, such as Euro pallets, can be picked up or dropped off automatically without manual intervention. This solution ensures a high level of efficiency in the material flow, reduces sources of error and enables continuous automation of your logistics processes.

Fully automated and autonomous outdoor AGV tugger train Factory Train from Neumaier Industry with roller conveyor load carrier for the automated loading of stationary conveyor technology or unloading on stationary conveyor technology.

With the conveyor belt load carrier, the good carriers can be picked up directly from driven roller conveyors/conveyors or discharged onto the driven roller conveyor/conveyor. The pick-up and drop-off height can be approached automatically by the lifting gear integrated in the load carrier.

- Loading/unloading on both sides

- Automatic transfer to powered roller conveyors

- Multiple load carriers can be picked up

Automated load carriers with telescopic forks

Our load carriers with automatically extending telescopic forks offer a flexible solution for handling secured/braked pushable goog carriers standing on the floor, such as trolleys, roll racks or pallets (crosswise and lengthwise). The forks extend automatically and pick up the good carriers precisely. They are particularly suitable for the automated transport of goods standing on the floor and for their safe delivery.

Fully automated and autonomous Factory Train outdoor tugger train from Neumaier Industry with telescopic fork load carrier for the automated pick-up and delivery of good carriers to/from transfer stations or directly to/from the ground.

The load carrier with automatically extending telescopic forks can be used to automatically pick up and drop off secured/braked pushable good carriers standing on the floor, such as trolleys/roll racks or pallets (crosswise and lengthwise).

- Single-sided loading/unloading

- Automatically extendable telescopic forks

- Automated pick-up of trolleys/pallets (crosswise and lengthwise)

Load carriers for manual loading processes

Many different load carrier systems are available for manual loading processes. These range from simple C-frames and E-frames to universal platform frames for flexible loading/unloading on both sides. You can find the basic load carrier systems for manual loading processes here.

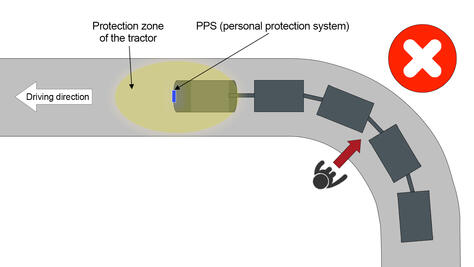

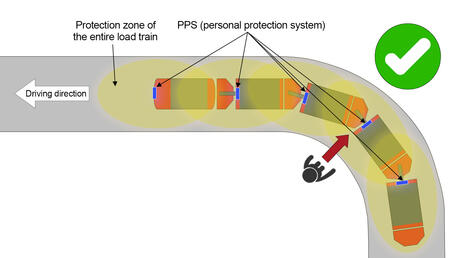

Personal protection system (PPE): Full monitoring of the entire autonomous tugger train

With the FT600 and FT900 automated Factory Train load train, not only is the tractor environment secured in the direction of travel, but the entire train is permanently and fully monitored by a personal protection system (PPS). From the tractor to the last trailer, the load train is covered with a "protective field", so to speak. Several safety scanners secure the load train, both the direction of travel and the lateral areas are permanently monitored. The safety scanners are integrated in the tractor and also in each individual load carrier. The safety scanners scan the surroundings and generate a warning and protective field around the FT600/FT900 load train.

When driving straight ahead, everything seems fairly straightforward. But how does the monitoring function work when cornering, when the safety scanners run the risk of identifying the train itself as an "obstacle"? Once again, the Neumaier Factory Train load train offers a solution. Thanks to innovative technology and the network of the entire train formation to work as one vehicle, the load train recognises the bend radius and reacts accordingly.

The protective field and warning area created around the automated load train adapts to the driving speed. If the load train detects an obstacle (e.g. a person) in its warning field, the train reduces its speed continuously down to 0 km/h (if necessary). During speed reduction, the warning/protection field sizes are adjusted according to the driving speed.

Outdoor driving with the automated load train Factory Train FT600/FT900

What was previously not possible is now possible with the new Factory Train FT600 and FT900 load train. Because the FT600/FT900 can also run automatically in outdoor areas. Neumaier AGVs can drive safely and autonomously outdoors. With a new innovative and patented solution, we can also use our vehicles safely and efficiently outdoors. The challenge was to use the PLd-safe outdoor laser scanner on the vehicle in such a way that it works in weather conditions such as rain and ensures that it remains available and does not recognize each raindrop as a hazard, causing the vehicle to malfunction and stop operating.

Cornering speed reduction and electronic braking system

Like the manually operated Factory Train load trains, the automated Factory Train FT600/FT900 also features automatic speed reduction when cornering. In this case, the entire train formation is decelerated during cornering. The speed remains throttled until the entire train has exited the bend and is driving straight ahead. This feature, which comes as standard with all models in the Factory Train series, eliminates the whiplash effect.

Another advantage of the automated Factory Train FT600/FT900 is an electronic single-wheel brake system with ABS and emergency brake function, which can be installed on all steering axles in the train. In automation, shorter braking distances mean higher driving speeds since the train stops at a shorter distance. In addition, the load train brakes evenly and comes to a gradual and safe stop in an extended state thanks to the use of the electronic single-wheel brake system. This prevents dangerous sliding of the load carriers and ensures that the entire train formation always stays in its track.

References indoor AGVs and outdoor AGVs

This might also be of interest to you

-

Automated outdoor tugger train Factory Train

Outdoor AGV: Autonomous driverless outdoor tugger train Factoy Train FT600 and FT900. -

References and Videos

Neumaier machines and vehicles in successful customer use: Automated guided vehicles and tugger trains. -

Autonomous (outdoor) forklift truck: Factory E-Truck FE600

Fully automated electric counterbalanced forklift truck for autonomous indoor and outdoor use.