Narrow-aisle AGV: Efficient high-bay automation with the automated narrow-aisle stacker FK600

Increase the productivity of your warehouse logistics with our innovative, fully automated FK600 narrow-aisle stacker. Equipped with high-precision, all-electric positioning axes, this automated narrow-aisle stacker sets new standards in speed and accuracy. Compared to conventional hydraulic systems, the automated narrow-aisle stacker enables an increase in productivity of up to 300 %, making your warehouse processes significantly more efficient.

The FK600 automated narrow-aisle truck utilises a unique, fully electric positioning tunnel with telescopic fork technology. Alternatively, the narrow-aisle AGV is also available with a swivelling push fork. The telescopic forks, which can be extended on both sides, allow pallets to be stored and retrieved quickly and precisely - without the need for a time-consuming swivelling function. Fully automatic storage and retrieval is performed by sensors and cameras that continuously monitor the process and check for plausibility. This means that manually stored pallets are picked up and retrieved precisely, which significantly increases efficiency.

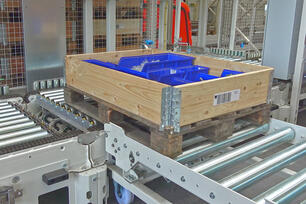

With our automated narrow-aisle stacker, pallets can be stacked and stored three high fully automatically. This innovative triple stacking technology increases storage density by an impressive 45%, allowing you to utilise more storage space in less space. A special clamping device ensures safe transport and perfect alignment of the pallets or pallet cages during the storage process.

Safety is the top priority for our fully automated high-bay warehouse: the FK600 automated narrow-aisle stacker is equipped with safety laser scanners and other safety devices all round. This ensures the protection of people, materials and machines during operation.

Automated narrow-aisle stacker FK600 at a glance:

- 300% more productivity of the narrow-aisle stacker due to precision positioning axes

- Tracking and lovation via induction

- Fine positioning via optical sensors

- Electronically operated telescopic forks extendable on both sides without swivel function

(alternatively available with swivel-push fork) - 45% higher storage density due to 3-fold stacking technology

- Clamping device for safe transport and alignment of pallets

- Integrated contour and weight control of the pallets

- Sensor-monitored storage/retrieval processes

- All-round safety monitoring with safety laser scanners

- Wifi radio connection to the MFC

References indoor AGVs and outdoor AGVs

This might also be of interest to you

-

Automated conveyor technology and order picking

Sophisticated conveyor technology and processes increase picking productivity at the automated high-bay warehouse by 35%. -

Logistics software and IT connection in the automated high-bay warehouse

Holistic logistics software solution and IT connection for the automated high-bay warehouse with narrow-aisle AGVs -

Autonomous high lift stacker: Factory Lift FL600 and FL400

Automated guided high lift stacker (AGV) with 2-way and 4-way steering technology.