Automated conveyor technology and order picking on automated narrow-aisle racking

Our innovative narrow-aisle solution increases picking productivity at the high-bay racking by 35%. Thanks to sophisticated conveyor technology, conveyor sections and roller conveyor trolleys, there is no need to use forklift trucks in the picking zone. Fully equipped, permanently defined workstations and several source sinks enable time-parallel storage and retrieval - for faster, more efficient processes.

Efficient lengthways serving process with multiple swelling sinks on the high rack

Optimise your storage processes with our lengthways serving process, in which several source sinks are arranged on the long side of the high-bay racking. Load carriers are automatically conveyed into the high-bay aisle via pass-throughs and can be picked up, stored or transported onwards by the automated narrow-aisle stacker.

This system significantly increases process speed and handling capacity. It avoids the dangerous and time-consuming manoeuvring of the narrow-aisle trucks outside the high-bay racking in the picking area. Short distances for the load carriers via direct pass-throughs and the ability to operate the source sinks from both sides ensure efficient processes. Additional picking and storage devices are also saved.

- No dangerous and time-consuming manoeuvring of the narrow-aisle forklift outside the high-bay racking in the picking area

- Short distances for the load carriers via direct pass-throughs

- Multiple source sinks for time-saving storage and retrieval

- The high-bay racking can be operated from both sides thanks to the arrangement of source sinks on both long sides

- Saving on other picking and storage devices

Optimised picking zones for efficient logistics processes

Increase the productivity of your warehousing with our ergonomic, efficient and safe picking workstations. Our fully equipped, fixed picking stations are designed so that the working radius of employees is clearly defined - handling machines such as pallet trucks or forklifts are therefore unnecessary. Instead, picking is carried out exclusively using special roller conveyor trolleys and innovative conveyor technology, which guarantees smooth and fast processing. Each workstation is also fully connected to the ERP and WMS system in terms of IT technology to ensure seamless data integration.

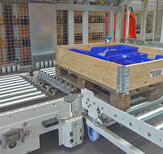

Modern conveyor technology and roller conveyor trolleys for precise load carrier handling

Unsere speziell entwickelten Rollenbahn-Trolleys sind individuell verfahrbar und ermöglichen eine flexible Übergabe der Ladungsträger an die fest installierte Förderstrecke, die sich entlang des gesamten Hochregals erstreckt. Diese kann je nach Bedarf variabel konfiguriert werden, um unterschiedliche Funktionsabläufe zu unterstützen. Beim Einlager-Prozess werden alle Ladungsträger automatisch geprüft, gescannt und dokumentiert – inklusive Art, Gewicht, Konturen, Barcodes und fotografischer Aufnahmen. Die Einlagerung des Ladungsträgers in das Hochregal erfolgt nach Priorität, Kommissionszugehörigkeit und Häufigkeit. Die automatische Ausrichtung der Ladungsträger vor der Einlagerung sorgt für eine schnelle und exakte Aufnahme des Ladugnsträgers durch den automatisierten Schmalgang-Stapler.

Conveyor and order picking technology at a glance:

- 35% higher order picking productivity

- Reduction of picking/storage equipment

- Fully equipped and firmly defined order picking zones

- Roller conveyor trolleys with docking function and backstop

- Partially to fully automated functional sequence of the conveyor line

- Automatic restacking of the load carriers on the conveyor line

- Automatic centring and alignment of the load carriers before the storage process

References indoor AGVs and outdoor AGVs

This might also be of interest to you

-

Logistics software and IT connection in the automated high-bay warehouse

Holistic logistics software solution and IT connection for the automated high-bay warehouse with narrow-aisle AGVs -

Neuamier demonstration centre for automated intralogistics

Experience automated intralogistics live in real operation at the Neumaier demonstration centre. -

Autonomous high lift stacker: Factory Lift FL600 and FL400

Automated guided high lift stacker (AGV) with 2-way and 4-way steering technology.