Fully automated high-bay warehouse with automated narrow-aisle stackers, conveyor technology and software solution

Discover our revolutionary concept for high-bay automation, which is specially tailored to the requirements of modern warehouse logistics. With our unique solution, we are setting new standards in high-bay automation through the use of automated narrow-aisle stackers and narrow-aisle AGVs. These high-performance technologies enable maximum storage density, minimise picking effort and at the same time offer flexible, requirement-specific adaptation to your warehouse processes.

Our automated narrow-aisle stackers are the centrepiece of high-bay automation. They are specially designed for narrow aisles and ensure efficient storage and retrieval as well as order picking in narrow storage areas. The use of narrow-aisle AGVs (automated guided vehicles) takes the automation of your warehouse processes to a new level. These fully automated vehicles navigate precisely between the shelves, optimise the use of storage space and significantly reduce personnel costs.

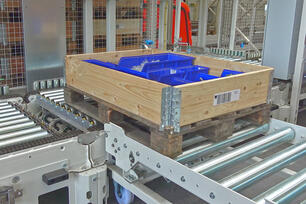

The Neumaier narrow-aisle concept for high-bay racking includes not only automated narrow-aisle stackers but also special conveyor technology for the smooth handling of all picking and storage processes. The system is complemented by a sophisticated operating concept with a comprehensive software solution and IT connection, which enables seamless control and monitoring of your warehouse logistics. You benefit from an integrated automation solution that guarantees maximum efficiency, flexibility and scalability.

Learn more about the Neumaier narrow-aisle solution here:

The fully automated high-bay warehouse with automated narrow-aisle stackers / narrow-aisle AGVs is impressive

With our high-bay automation, you can significantly increase productivity: the automated narrow-aisle stackers achieve 300% higher productivity thanks to precision positioning axes that enable exact control and fast processes. In addition, our triple stacking technology ensures an impressive 45% higher storage density, which makes optimum use of the available space. During order picking, you benefit from a 35% increase in productivity.

- 300% more productivity of the narrow-aisle stacker due to precision positioning axes

- 45% higher storage density due to 3-fold stacking technology

- 35% higher productivity at order picking

References indoor AGVs and outdoor AGVs

This might also be of interest to you

-

Autonomous high lift stacker: Factory Lift FL600 and FL400

Automated guided high lift stacker (AGV) with 2-way and 4-way steering technology. -

Driverless unterride AGV: Factory Shuttle FS400

Underride AGV: Compact and driverless transport system (AGV) for modern factory automation. -

Neuamier demonstration centre for automated intralogistics

Experience automated intralogistics live in real operation at the Neumaier demonstration centre.